Understanding vacuum

It is not my intention to give a lecture about vacuum nor to be complete in my explanation. See Wikipedia or other encyclopedia.

In the composite practice it is necessary to know a little more about the vacuum pump, the use of measuring units and to handle some pitfalls in the field of vacuum. At the start of my composite adventure I had wished this composite related vacuum information would have been available in that time and in such a way I could understand. With vacuum resin infusion the devil is in the details and it is these details that make the difference.

So, to operate vacuum infusion you just need some more knowledge and a little more understanding of vacuum is a good start.

Don't think I'm writing this down only for the coming vacuum infusion enthusiasts or other visitors to my website as this is at the same time a refresher for my own knowledge of the matter.

And regarding my workmanship with composites, that has reached an acceptable level now as I went through a steep learning curve since the beginnings in 2000.

So, coming vacuum infusion enthusiasts, here it is.

Vacuum

The quality of a vacuum refers to how closely it approaches a perfect vacuum. The perfect vacuum is a volume of space that is essentially empty of matter. In practice achieving complete emptiness is impossible. Even the outer space is not empty of matter. Go study quantum mechanics to understand why.

The quality indicators are low vacuum, medium vacuum, high vacuum, ultra high vacuum, extremely high vacuum and outer space. In this vacuum terminology the construction of composite parts with help of a vacuum process operates in the low to medium vacuum rates, being not better than 99% of atmospheric pressure. The other four indicators are for vacuum quality between 99,999% etc. and 100% of atmospheric pressure.

For the vacuum infusion jobs I often speak about “high vacuum” , “full vacuum” or “deep vacuum” but what I mean is the use of a vacuum that can be as low (or high?) as 99% of the outside pressure. Say 29.5 ″Hg or 1 Bar. Wow, that is a lot, but in fact in vacuum terminology this is considered as “Medium Vacuum”.

Now that we know that please forget it immediately. I prefer to speak about “full or high vacuum” meaning to achieve the best possible vacuum our vacuum pump is capable of. Most rotary vane pumps are capable of achieving an absolute pressure of 50 mbar (1,5″Hg) or better.

I hear you saying “But what about pulling 29″Hg or better I'm reading in all these websites about vacuum bagging, resin infusion, vacuum pumps, etc.”

Now that is food for misunderstandings. I will try to explain.

.

Units (SI, Metric, Imperial, Mercury)

To understand vacuum you need to know a little about how it is measured in units of pressure. The SI unit for pressure is the pascal (Pa), equal to one newton per square meter (N/m²) Meteorologists often prefer the hectopascal (hPa) for atmospheric air pressure, which is equivalent to the popular unit millibar (mbar). Because pressure is commonly measured by its ability to displace a column of liquid another unit in use is the inch of mercury (″Hg) and the millimeter of Mercury (mmHg). 1 mmHg is equal to 1 Torr, the unit named after Evangelista Torricelli, an Italian physicist and mathematician who discovered the principle of the barometer. And finally a more obscure unit (forgive me, my upbringing is metric ;-) is the imperial pound per square inch (psi)

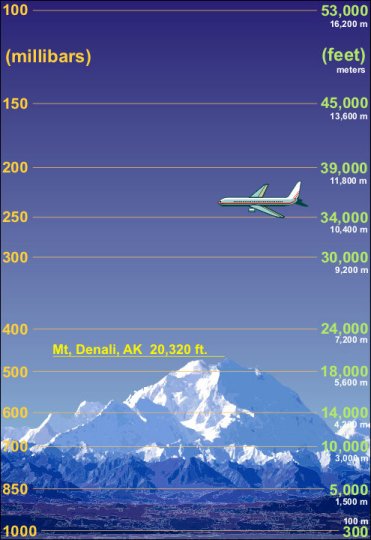

The atmospheric pressure that we experience on earth is caused by the weight of air above the measurement point and for this reason varies with the altitude above sea level . The standard atmosphere (atm) however is an established constant. It is approximately equal to typical air pressure at earth mean sea level and is defined as follows:

1 atm = 760 Torr = 29,92″Hg = 14.7 psi = 101.3 kN/m² = 1013 mbar = 1013 hPa

In practice, atmospheric pressure at sea level will vary from about 980 mbar to about 1030 mbar, but pressures below 900 mbar have been recorded in the eyes of cyclonic winds and over 1080 mbar has been recorded under very still and cold conditions. At the summit of Mount Everest atmospheric pressure averages about 300 mbar.

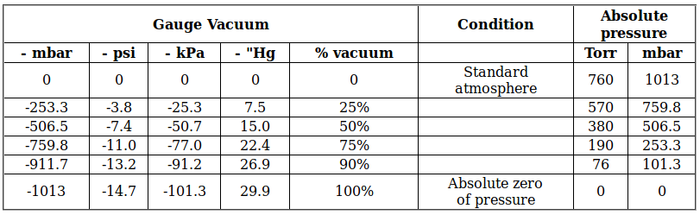

Gauge vacuum and absolute pressure

The barometer in our home or boat gives an absolute (atmospheric) pressure. The reading is the pressure above the absolute zero of pressure (or perfect vacuum).

The vacuum in the vacuum bag or resin trap is measured with a vacuum gauge and the reading is relative to the external atmospheric pressure, in units on the barometric scale or as a percentage of atmospheric pressure. This relative measurement is called gauge vacuum and is the pressure difference below the atmospheric pressure. Actually the vacuum gauge works the opposite way to the barometer.

Thus the absolute pressure in the vacuum bag or resin trap is equal to the current atmospheric pressure minus the vacuum pressure in the same units. Or the driving force for the resin to get into the part is the difference in the same units between the atmospheric pressure and the absolute pressure in the bag.

So, the good news is that in our low country (the Netherlands) I get more pressure and can infuse over a longer distance than someone building in the mountains of Italy or Colorado .......

......... the bad news is that I live in a wet country at the end of the North Atlantic track of depressions (= low pressure) and the guys in the mountains have more frequent fine weather (= high pressure)

This means that the residual pressure inside the lay-up may differ from the gauge reading because of changes in atmospheric pressure due to changing weather conditions and altitude variations.

For instance at sea level and standard weather (29.9 ″Hg) a gauge vacuum of -25.9″Hg is equivalent to an absolute pressure of 4″Hg. In other words, the vacuum gauges that read, for example, -25.9″Hg at full vacuum is actually reporting 4″Hg, or 136 mbar. That is still in the low vacuum range.

While the vacuum infusion takes place preferable in the medium vacuum range ( is a vacuum (absolute pressure) less than 1″Hg (35 mbar) the accuracy of the vacuum gauge is in the range of 1.5″Hg (50 mbar) So, here comes the wish for an absolute pressure gauge.

An absolute pressure gauge measures relative to the absolute zero of pressure and is unaffected by weather or altitude. Various pressure scales may be used for the two different methods, with the relationships between some of the more common ones tabulated below:

Note that the % vacuum reading is an easy one not depending of SI or Imperial or whatever unit. Although, it will be clear that the scientist operating in the, for us simple composite workers unreachable, ultra- and extremely high vacuum ranges only use the absolute pressure reading. However, the HI-Tech composite builder will follow that path too. More about that at the end of this page.

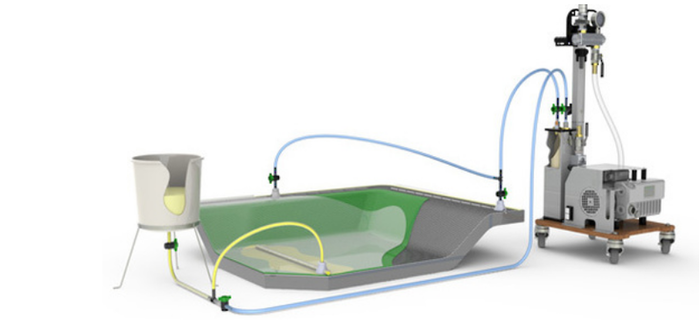

Vacuum pump and size

And what about vacuum pump size? Food for more misunderstandings I'm afraid.

Consider your vacuum bag, be it for a small panel or a 40ft yacht hull. Achieving a vacuum requires an air flow from the bag to the vacuum pump. This is not the best part of a serious vacuum pump (low volume/high pressure pump - not much airflow but lots of power) and the smaller the pump, the less air flow. This means that it will take a while till most of the air is out of the bag. For the small panel bag say 2 minutes and for the 40ft boat hull bag maybe 2 hours. The “big pump” needs seconds and minutes to achieve the same.

That's it, that's the difference between a small pump and a big pump ! The bigger pump evacuates the bag much quicker than the smaller equivalent. The pump size is addressed as the quantity of airflow the pump is capable to evacuate in a certain time, in cubic feet per minute (cfm) or cubic meter per hour (m3/hr). It says nothing about the vacuum quality.

The real quality difference of vacuum pumps arises when most of the air is sucked out of the bag and a deep vacuum must be achieved. And that is not depending of vacuum pump size! I infused my 40ft. boat hull with a 1.5 cfm vacuum pump and full vacuum. Regarding the vacuum quality there is really no difference between a small pump sucking on the bag or a big pump. However, there are two very important conditions: no leaks and no out-gassing issues. More about that further down in this page.

The real quality difference of vacuum pumps arises when most of the air is sucked out of the bag and a deep vacuum must be achieved. And that is not depending of vacuum pump size! I infused my 40ft. boat hull with a 1.5 cfm vacuum pump and full vacuum. Regarding the vacuum quality there is really no difference between a small pump sucking on the bag or a big pump. However, there are two very important conditions: no leaks and no out-gassing issues. More about that further down in this page.

What to do when you have a small (low cfm) vacuum pump and no patience to wait for action in the bag?

Use your shop vacuum cleaner to remove the bulk of the air. A vacuum cleaner is a high volume/low pressure pump - lots of air flow but little real power and not capable of achieving a gauge vacuum better than 400 mbar (the better ones) or 200 mbar when it is your old domestic Hoover. Don't try to remain such a vacuum with your shop vac as most of them have a motor cooled by the air passing through it, and so without vacuum leaks that shop vac won't live long enough to survive the curing time of the resin.

If you have just one or two real small vacuum pumps and there are leaks in the bag who are too big to hear, you have a problem and the search can become very frustrating. My patient wife, who has a much better hearing than I, was still able to resolve it for me. Without her you need more time or a bigger pump. With a big cfm pump, the individual leaks will be bigger and easier to detect. You can get the same effect with multiple small pumps. In this regard is a silent pump much more convenient than a noisy pump.

Most common pumps are the venturi pump, the diaphragm pump and the rotary vane pump. My experience is limited to the use of the rotary vane type vacuum pump. For my composite work and specially vacuum infusion, the pump must be capable to achieve a gauge vacuum of at least 900 mbar (26.6″Hg), but preferable better. In absolute pressure this is about 100mbar, but preferable lower. Good quality single stage rotary vane pumps are able to achieve a vacuum as low as 0,1 mbar (which in fact is too low for composite works, more about this later)

The double stage rotary vane pump is not for composite work as these are made for high vacuum. It don't like to run continues in the lower vacuum ranges.

Last but not least, the smaller vacuum systems runs on single phase 230 V, 50 Hz power in Europe or 110 V, 60 Hz power in USA. No need for a three phase electrical system.

Guess what, I am an advocate of small vacuum systems ;-)

Cheap vacuum pumps can be found on Ebay and similar sites, new or used, which is often superfluous laboratory equipment or used in hospital (MRI), air-conditioning or refrigerator maintenance.

Another - and real cheap - vacuum system is the DIY vacuum pump, made of a (old) refrigerator compressor, or similar. Please Google on these search terms and you will find some nice websites with how-to-build instructions. Looks nice, however, I wouldn't trust my expensive 40' boat hull infusion with such a system.

So, only for the hobbyists among us for whom the vacuum resin infusion technique is not enough challenge.

A drawback of the small (and cheap) oil filled rotary vane pump may be that these have often a less effective filter on the exhaust side of the pump. Especially when running at poor vacuum, whether or not affected by water vapour, they can discharge oil from the exhaust. Apart from the mess and risk of running out of oil over a long run, there's also a risk of oil vapour contaminating the composite materials.

For purchasing a reliable small but professional vacuum system that can be used by the individual builder as well as by the professional boat building plant as part of a multiple vacuum system read my advice at the end of this page.

Yes or no a vacuum switch

With the slow hardeners we use in the vacuum infusion technology it is common practice to run the vacuum pump for 12 hours or more (and keep it running overnight or even the whole weekend), which is not any problem for the pump. The oil sealed type of vacuum pump most commonly used for infusion work is designed to run non-stop between oil changes, which can be up to 500 hours.

Besides of saving some cost for energy I can't see any reason to use a vacuum switch. To be effective, a vacuum switch will always limit the ultimate vacuum of the pump. If it cycles on and off at all, there must inevitably be a decrease in vacuum to activate the switch. If you set the switch too fine and too close to max vacuum, it will cycle too frequently and destroy the pump motor.

Further more electric motors do not like frequent turning on and off, as the starting currents are much higher than running currents. Starting too frequently can cause major overheating problems for the motor.

But most important reason to not use a vacuum switch in the oil sealed type of vacuum pump most commonly used for infusion work is that the pump needs to run hot to discharge the water vapour often associated with composite materials. When hot, the pump will boil the water off. When cold, the water will emulsify in the oil and shorten the oil life and cause corrosion inside the pump. Water vapour is the “invisible enemy” with behind several vacuum problems in composites and I try to explain why in the chapter “vapour pressure” further down in this page.

This is also the reason to run the pump warm for at least half an hour before starting any infusion work.

Large central vacuum systems vs. small individual units

I dare to say that the large centralized vacuum systems often found in the (older) boat production yards are outdated. The use of multiple smaller vacuum systems in the composite plant is a much more versatile application of vacuum for the production of composite parts and boat hulls. Preparing the infusing of a big hull one can use a number of small systems for the initial evacuation and leak testing and maintain the vacuum and infusing with just one vacuum pump. At the same time the production of other composite components continues without having to worry about anyone else's vacuum needs. The shop won't need any expensive vacuum lines running all over and you won't have to deal with vacuum leaks all the time. For security the maintaining of vacuum is guaranteed by the presence of more than one vacuum system.

Large central vacuum systems cannot usually achieve such a high vacuum level in the vacuum bag and almost never do if there are any other vacuum applications occurring elsewhere in the plant at the same time. Even if the vacuum pump of a central vacuum system has better vacuum capability than the pump used in a small vacuum system and even if many times larger in capacity, a central vacuum system typically won't "out-suck" a good but small vacuum pump.

Why is this?

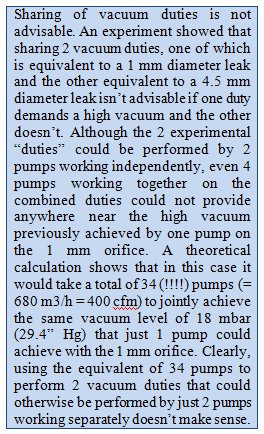

One reason is that the long and complex pipe work normally associated with central vacuum systems is prone to leakage. Even a very small hole will cause a significant reduction in the maximum vacuum available at the job, as will be shown further down in this chapter. Another, and probably more important, reason is that vacuum cannot easily be "shared" among multiple vacuum duties requiring different vacuum levels at the same time. Unless the central system's pump capacity is enormous, what normally happens is that the biggest vacuum demand at any one time sets the available vacuum level for all vacuum duties occurring at that time. If one duty is vacuum bagging a large boat hull at 70% vacuum and another is infusing a small component, the maximum vacuum available for the infusion will be 70% - even if the central pump is theoretically capable of achieving 99.9% vacuum.

What can you do if you already have a central vacuum system in your shop and want to introduce vacuum infusion?

One approach would be to install zero-loss vacuum regulators at each vacuum connection in the plant and adjust each of them to provide no more than the vacuum required at each connection. Properly adjusted zero-loss regulators would reduce the overall vacuum load and increase the maximum vacuum level available throughout the plant. Because the central system is likely to have considerable potential for leakage, the vacuum level available for infusion may still be poorer than the independent machine approach and still likely to use somewhat more energy. A disadvantage of zero-loss type vacuum regulators is that they are relatively expensive. A further consideration is that if they are not correctly adjusted they serve no benefit at all. Note that conventional vacuum regulators, which simply admit air to reduce vacuum serve no useful purpose whatsoever on a central vacuum system. They are, in effect, just controlled leaks and they will not improve the overall vacuum level. In fact the worst vacuum setting will limit the whole plant!

Vapour pressure

Evaporation and sublimation into a vacuum is called out-gassing. All materials, solid or liquid, have a small vapour pressure, and their out-gassing becomes important when the vacuum pressure falls below this vapour pressure. In man-made systems, out-gassing has the same effect as a leak and can limit the achievable vacuum.

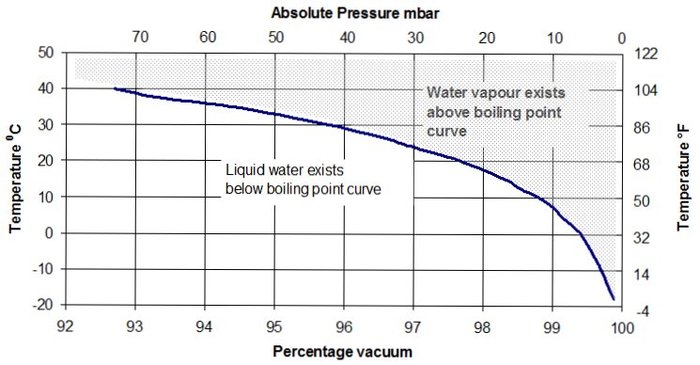

Water vapour is often the unseen cause of vacuum pump problems. It originates from the water carried in the atmosphere. This is absorbed into fabrics and onto the surfaces of moulds and bagging films. Under certain conditions of vacuum and ambient temperature as shown in the water boiling chart, water will be evaporated from these materials and transported to the vacuum pump. Especially if the pump is cold, the water vapour will condense into liquid water on the exhaust side of the vacuum pump. The liquid water may circulate with the pump oil and this can harm the pump in a number of ways. It will convert back into a large volume of water vapour on the inlet side of the vacuum pump and its presence will reduce the effective capacity of the pump. Liquid water in the pump will cause internal corrosion when the pump is stopped for any length of time.

Some water vapour will be present in almost every vacuum situation, but there will be a large increase in volume when liquid water starts to boil. Water will boil at reducing temperatures as the vacuum level increases. Any combination of temperature and vacuum above the boiling point curve will generate large volumes of water vapour until all of the water has boiled away. A slowdown in vacuum pump performance should also be expected until the vacuum pump has removed the water vapour and discharged it from the pump exhaust.

Another source of vapour may be resin solvents. Particularly polyesters and vinylesters will outgas under vacuum. The level of vacuum for this effect to take place is dependent on the vapor pressure of the solvents present in these resins. Resin suppliers will be able to advice these vapor pressure and the correct level of vacuum to be applied at the end of an infusion to avoid unnecessary out-gassing of the solvents required for the curing process.

So, the use of special formulated vacuum infusion resins is not only for low viscosity properties but also to prevent out-gassing problems. Most epoxy resins are quite save in this regard.

Some foam types are known to have out-gassing issues, one of the reasons why I choose for Corecell as the core in my composite parts and boat hulls.

To avoid water vapour problems, keep raw materials dry during storage (ideally in a dehumidified area) and keep the work area as dry as practical. To avoid resin vapour problems use an appropriate infusion resin and regulate the vacuum level after the infusion by maintaining a vacuum level slightly poorer than the vapour pressure of the resin solvent.

If the vacuum level reached appears abnormally poor even though all leaks have been carefully sealed, high vapour pressure might be the culprit. When checking for leaks , always conduct the pressure-rise or leak-back test at a vacuum poorer than (or absolute pressure higher than) the boiling point pressure. For example, when leak testing a vacuum bag at an ambient temperature of 30°C (86°F) commence the pressure-rise or leak-back test at a vacuum poorer than 95% vacuum or an absolute pressure higher than 50 mbar. (or 0.73 psi or 1.5″Hg or ..... dammit, I wanna get rid of this converting thing, please check convert-me.com/en/ which is my favorite online converter!)

Food for thoughts: the simple numerical conversions can't handle the difference between gauge vacuum and absolute pressure. On Convert-me.com/pressure, 0 mbar = 0″Hg, whereas - as you now know - 0 mbar absolute = 29.92″Hg (at sea level in standard atmosphere).

The significance of vacuum leaks

A very small hole will cause a significant vacuum leak. Even a 1 mm (0.04″) diameter hole will cause enough air leakage to noticeably affect the performance of a 20 m³/h (12 cfm) vacuum pump. A hole of 4.5 mm diameter (less than 3/16″) will nearly halve the vacuum performance of a 20 m³/h (12 cfm) vacuum pump.

Where vacuum bagging can be more tolerant regarding leaks, with vacuum resin infusion leaks in the bag or mould are impermissible. This is because an air leak into the lay-up will create a line of air bubbles from the origin of the leak all the way to the exit of the lay-up. If the bag and associated parts don’t hold vacuum, you will not infuse quality products no matter how hard you try. Resin penetration in the region of this line of bubbles will be reduced with a resulting reduction in structural properties and poor appearance. But the great thing about the infusion process is that you can pre-test for vacuum integrity before you shoot the resin.

The existence of vacuum leaks can be checked prior to infusion with a pressure rise test. First be sure there are no leaks in the vacuum pump, resin trap and connections to each other. After evacuating the lay-up to maximum vacuum for as long as practicable, close the vacuum line between pump and resin trap and observe the change in vacuum on the vacuum gauge. A slight pressure drop is normal but the question is how fast this occurs. A visible movement is easy, go back to the vacuum bag and continue searching for big leaks. A drop down of 50 mbar in 10 min is about the maximum (for me) that is acceptable. This doesn't mean there are no leaks anymore but finding them will take a lot of effort.

As I've said before, because of my bad hearing I need my wife to find the leaks by the hissing sound they can make. However, you can't hear a big leak with a small pump so yes or no a hissing sound depends of the size of the leak in relation to the air flow capacity of the pump. This is assuming you can hear anything over the noise of the vacuum pump, so a silent pump is recommended. Leaks you can't hear are either big or very small. You have to find the big ones with your eyes and hands, by securing all suspicious spots. The ultrasonic leak detector is for locating the small leaks inaudible to human hearing. The ultrasonic leak detector converts the ultrasonic sound produced by leaks to an audible level and also visually displays the leak on an LED meter.

Finding and repairing vacuum leaks, especially in resin infusion applications, can be a complex process, involving issues such as mould (hull) quality, bag quality, bag connections, bag sealing techniques and vacuum tubing quality. I only use use good quality consumables such as bagging film, vacuum tubing and connections of a reputable composite materials supplier. While the consumable cost may be higher than that of lower cost consumables such as agricultural film and irrigation tubing, the time saving from reduced leak problems is likely to outweigh the material cost saving. Don't underestimate that!

So, when you don't have to worry about the air tightness of the consumables the only sources for leakages is the bag and the mould or hull. In my practice, when I think there is still a (very small) leak that I can't find, I just start the infusion and if there is still a leak it's easy to see by the bubble track and you have to pay some local attention to the bag sealant. If the leak is in the mould or hull you have most likely a problem. But no panic. There are various ways and tricks to resolve this. It never happened to me that I've lost a part by a failure in the infusion system. Please read the tips and tricks chapter at the CD of my Resin Infusion Starters CD.

There is still left a pitfall in leak testing, which is out-gassing, explained in the previous chapter. Moisture and solvent will create vapour that may act like a leak under high vacuum conditions. To avoid the risk of residual water or solvent vapour creating a “false leak” it is recommended commencing the leak rate test at about 90% vacuum.

Now, if you are still hanging on to this tough stuff, you must be a suitable candidate for using a digital absolute pressure gauge to take the vacuum readings, explained in the next chapter..

Dial- or absolute pressure gauge

A digital absolute pressure gauge, also called precision vacuum gauge, will respond to pressure changes more quickly than the dial gauge normally used on vacuum pumps and resin traps. The use of this device reduces the vacuum gauge to a general purpose indicator.

The residual pressure inside the lay-up may differ from the gauge reading because of changes in atmospheric pressure due to changing weather conditions and altitude variations. Going Hi-Tech for high quality resin infusion work, it is better to use an absolute pressure gauge to measure vacuum. It measures relative to the absolute zero of pressure and is unaffected by weather or altitude, so you know exact what is happening inside the vacuum bag.

As we learned in the vacuum pump section of this vacuum epistle, a good quality oil lubricated vacuum pump suitable for high quality vacuum infusion or pre-preg work will achieve an absolute pressure in the range of 10 mbar to 20 mbar above the absolute zero of pressure at the pump. It is not uncommon for this type of pump to achieve absolute pressures in the bag in the range of 20 to 30 mbar.

If we want to confirm that a bag has been evacuated to this degree of vacuum, the gauge used needs to be accurate in this region. This is asking the impossible of a conventional vacuum gauge which will experience inaccuracies of at least +25 mbar from weather variations alone, plus variations due the accuracy of the mechanism within the gauge, typically between 1 and 3% of full scale, perhaps another +30 mbar.

It will be apparent that a vacuum gauge with a total accuracy of +55 mbar is not an appropriate instrument for measuring an in-bag vacuum of 10 to 30 mbar. With reference to the diagram and ignoring the effect of inaccuracy arising from the gauge mechanism, it can be seen that on a "good" day the vacuum pump will achieve a vacuum of 30.1″Hg and on a “bad” day it will achieve only 28.6″Hg.

In fact, the pump is not having good days and bad days, it's the weather that is causing the changed reading. You will see that the variation between a good day and a bad day is 1.5″Hg, which is far more than the 10 mbar (0.3″Hg) we are trying to measure.

Another complicating factor and another reason for understanding the meaning of absolute pressure is the effect of moisture retained in composite materials. For accurate in-bag vacuum measurement you need to use an absolute pressure gauge.

Incidentally, absolute pressure gauges are excellent barometers, every serious sailor should have one.

Vacmobiles

When you are really serious about a vacuum pump there is just one stop shopping at Vacmobiles.com /

They are the real specialist and when you have a technical query in vacuum please email the Vacman

| « Previous Next » |