Construction

The preliminary study for such a boat building project is in fact the nicest phase of the construction. I think it's important to put myself in the designer's mind to find out why it should be built this way. Gradually you start to understand more and more and you are able to make the right choices and decisions.

Finally it takes only some guts to convert such a preliminary study eventually into a contract for the supply of a quantity of pallets of resin, fiberglass, foam, etc.

Construction plans

I would have never undertake such a huge project without the super detailed building plans of world class designer Ian Farrier. Every part of construction is very well worked out in detail. Just follow the indications exact as composite building is something I initially still do without any feelings in respect of strengths.

That said, there is still much room for personal insights and creativity so scattered properly put to the test.

Working with wood or steel give me direct indications of strength and stiffness. Composite building is much different. Create the best working conditions, follow the recipe, wait for the hardening and trust the result. In my professional job we do it with sand, gravel, steel, cement and water (reinforced concrete). For this project it is foam, fabrics and epoxy. It is the designers recipe that guarantees the strength and stiffness.

A lightweight and strong result is the most important thing so one has to ignore one's natural pressure (as most amateur-builders have) to make things stronger and heavier. Throughout the building process a checklist instruction system is used that keeps the work in order and ensures each job is done correctly and in the most efficient way.

Construction method

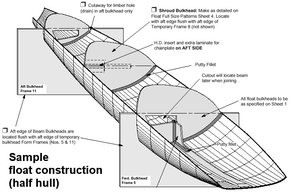

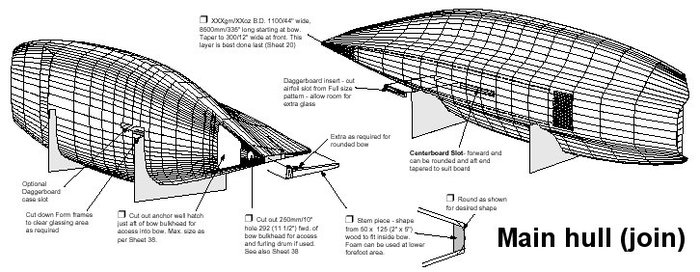

The key factor in Farriers building method is building half hulls, who are later joined at the centerline.

The center hull, the cabin sides, roof and most of the deck can be combined and all made at the same time. Many of the interior panels can be added before the hull is joined. An overlap join is required down the center, but this is exactly the place where any extra glass-reinforcement should be, for stiffness, and abrasion resistance. This method is much more easier and faster than the traditional hull-with-deck joining.

Where conventional methods of one-off yacht constructions are still based on a male mold, Farrier uses a female mold to build in the hull. Advantages over the old male mold method of foam core construction are all the screws are on the outside and stiffening bulkheads are added before the hull is removed from the mold. Anyone who has had to climb inside a male mold to remove the screws will appreciate the external screws, and once the hull is removed, one is not presented with a huge flexible hard to handle ″whale″.

Another advantage that should not be underestimated is that when using vacuum in a female mold, a better laminate is created with less risk of wrinkles. After all, the fiber stack is compressed into a larger space and the fibers experience a tensile stress. This is in contrast to a male mold, where the fiber stack is pushed into a smaller space and the fibers experience a compressive stress, with a chance of wrinkling.

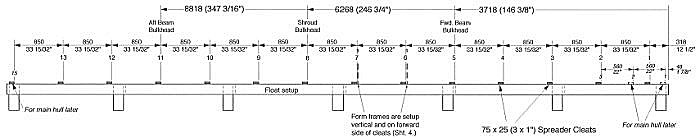

The construction process starts with making the so called ″Strong Back″. This is the basic foundation on which the hulls are built. Its basic purpose is to provide a true flat and level surface on which the temporary mold frames can be set up on. This temporary frame sare made of 18mm MFD and are spaced by 850 mm.

Usually, the trimaran hull was built up from longitudinally narrow foam strips that are connected to the mold frames and to itself and so creating a closed hull(part).

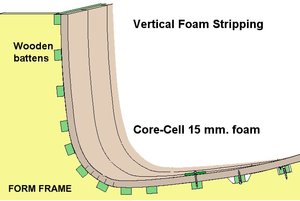

But with the introduction of the F-39 design, the construction method has been radically changed into wider foam strips with interconnections parallel to the building frames. The so called method of vertical foam stripping.

Vertical foam stripping

To make that possible, the building frames are connected by fore and aft battens that are spaced every 100-150 mm. or so, even closer in tighter corners. To make it myself easier I made the cut out of the hull lines wider so I can fix the battens without millings on the frames.

The resulting wooden framework, or female mold, is then planked with foam strips with joins at right angles to the battens. The foam strips needs to be thermoformed to get them in the desired shape. After some trial and error exercise I found out that this is best done with a heatgun and with strips of a maximum wide of 400mm. Together with 300mm wide strips this also turned out to be the most economical size, getting 3 or 4 strips out of one standard sheet of 1220x2440mm. (4′x8′). Self tapping screws, screwed from the outside, hold the foam down and to the battens. However, the resulting holding force of the screws in the foam is not so good. A good thermoforming technique is necessary to get the curved foam strips without tension down to the battens.

I glue the joins afterwards with thickened epoxy. Once glue has set, there is a half foam hull, ready to receive the inner glass laminate. Together with the later-added laminate on both sides, this results in the sandwich structure which is the structural basis of the boat hull.

It's a boat

Once internal glassing is complete, all internal stiffeners and bulkheads are applied. The bulkheads sit on a wet resin putty filled bed and are then glass taped to the hull, wet in wet for good bonding and without the ugly sanding. The hull is then removed from the mould and turned over to laminate the outer skin. The procedure is the same as with the internal glassing. For the second hull half the form frames are reversed and the same operation starts again.

After finishing the hull halves are joined together with epoxy glue and inside and outside glass tape over the center line.

So far the assembling method recommended by Farrier. Even though I've done it a little differently made possible by my method of vacuum infusion. In short, it means that I have made the exterior laminate of the two hull halves in one resin shot. See later in this chapter.

What follows is the building of all other structures, the interior, the beams, the daggerboard, the rudder, hardware, engine etc. and by far the worst job: fairing-sanding-painting.

Cored hull

All parts of the hull construction are a sandwich of foam and reinforced epoxy. The reinforcement consists mainly of a non-woven glass fabric. In places where great forces occurs, like in the beams, the glass is replaced by carbon. These modern high strength fibers makes it also possible to replace the traditional used materials like aluminum and stainless steel for rigging and hardware by modern and stronger substitutions like carbon and dyneema.

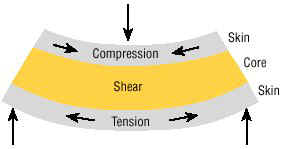

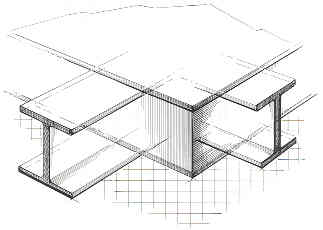

Sandwich Construction has been well established in boat building for many years. Like the civil engineer who use I-beams in the construction, the yacht designer specify the sandwich construction for much the same reason: to increase the stiffness while at the same time reducing weight.

The engineering theory shows that the flexural stiffness of any panel is proportional to the cube of its thickness. The laminate skins act as the I-beam flange and the foam core act as the beam's shear web. While the laminate is put into compression or tension, the foam core is put into shear. It therefore follows that one of the most important properties of the foam is its shear strength and stiffness.

Core

Core materials are cedar (nature's honeycomb but heavy), end-grain balsa (water resistance is very bad), honeycombs (expensive, not so amateur-friendly), foam and prefabricated combinations of these. Balsa, foam and honeycombs are mostly used in rigid molds by professional builders.

Cedar and foam makes it possible to "construct" a hull with simple male or female frames and without the need of full molds. With foam I don't mean the well-known foams used for thermal insulation applications (polyurethane, polystyrene), who are completely unsuitable for structural applications in a marine environment, but the modified (cross-linked PVC) or unmodified (linear PVC) structural PVC foam.

Of course the designers preferences and specifications are of vital importance and the core materials must suit the calculations and worked out building method.

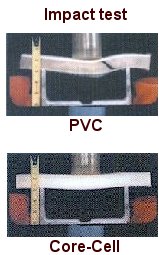

I choose for Corecell foam from former Canada's ATC-Chemicals but nowadays SP-Systems, to be the structural foam. More than the cross-linked PVC-foam (like Divinycell) but less than the linear foam (like Airex) this SAN-based foam is more flexible to suit the hull lines and curves necessary for Farriers vertical foam stripping method. The handling characteristics are better and thus easier to work with. In fact Corecell combines the best of two worlds, the strength and toughness of the cross-linked types and the good impact strength and flexibility of the linear types.

Impact tests shows that a sandwich with Corecell offers more resistance against impact forces than cross linked pvc. Corecell is accepted by Lloyd's Register of Shipping. Another issue is that with relatively thin skins, PVC foam outgassing has been an issue, which does not happen with the Corecell.

Unfortunately, the main disadvantage here in the Netherlands is the price, about 50% more than the other foams. Another disadvantage is the combustibility. It burns like hell (Divinycell doesn't). But the resin isn't any better. The prevention of fire on board will be (as always) an important safety issue. In fact, as I see it, fire is the one and only danger whereby this trimaran can sink.

Corecell A500 80 kg/m3 is used for the hulls and beam bulkheads and A1200 200 kg/m3 is used as high density inserts for the mounting of hardware. Corecell T400 is used for the interior panels. The core thickness is 15 mm.

The quality of cored hulls in series-built boats can still be disappointed by the pre-cured precut foamThe foam in the sandwich is equally massive everywhere, as it is thermoformed on the spot, so any air inclusions are not possible. This is not to say of other building methods where sheetcontoured foam, pre-cut with scrim backing, has been used. That foam will follow the shape of the mold quite easy, e advatage of that foam is that it

Fiberglass

A fabric is defined as a manufactured assembly of long fibers of glass, carbon, aramid or a combination of these, to produce a flat sheet of one or more layers of fibers. Most fabrics in the F-39 are non-woven Biaxial 0/90 and 45/45 fiberglass. Where concentrated forces are to be expected, the fabric is of the Unidirectional type. The majority of these UD-fibers run in one direction only.

Both fibers type are non woven. Because of the interlacing of warp (0°) fibers and weft (90°) fibers the woven fabric will lose a certain degree of strength due to crimp and the wrinkles and kinks. The fabric I use is made by a stitching process, which effectively combines two layers of unidirectional fibers into one fabric. Because of the fibers in these layers are kept straight and thus eliminating the crimp and shear factors that generally affect the strength and stiffness values of a standard woven fabric, there is a significant increase in mechanical performance. Another advantage of this type of fabric is the higher glass/epoxy ratio by the increase packing of the fiber which reduces the quantity of resin required. These knitted cloths have just less interstitial space for the resin.

For structural and weight reasons the fiberglass is replaced for carbon in some parts of the construction. These are mainly the beams, chainplates, daggerboard and rudder. I don't believe in local carbon reinforcements in combination with glassfiber. It's all or nothing.

Resin

Polyester or Vinylester are suitable resins and relative cheap. In fact, the design is engineered with polyester in mind. It is a common practice to use CSM (chopped strand mat) between woven rovings and foam and roving layers to help prevent interlaminar shear failure. With the prefreable knitted bi-directional fabrics, now many believe csm is not necessary due to the flatter and smoother interlaminar bonding surface. However, many also still believe csm should be used with knitted fabrics and polyester resins.

Although, in the early seventies I built about 30 canoes in polyester, I have never become a fan of it. At that time epoxy was simply not yet available. With the above in mind and remembering the nasty smell of styreen, my choice of resin is an easy one.

Epoxy resins have far more better mechanical and physical properties and is much more forgiving. The balance of properties epoxy can offer is hard to match. Higher compressive properties combined with higher toughness, higher adhesion with lower shrinkage, outstanding fatigue performance, low moisture absorption and (by virtue of their different curing chemistries) a complete absence of potential to suffer osmotic blistering.

So the choice between epoxy or polyester/vinylester for the "high-tech" F-39 is no question for me. The difficult part here is to choose the brand.

There is quite a price difference between known brand names and unknown names but what is the difference? For my skills and the building method, especially with regard to my wish to compact the laminate under vacuum, the epoxy system must be flexible according to the curing schedule. There must be enough (gel) time for doing the job. Health and safety is another important issue (with epoxy even more than polyester).

I finally decided for the Bakelite AG, a German company and the trailblazer in production of epoxy resins. This decision was also made because of the knowledge in the field of vacuum technique and the technical support I can get from the supplier. For the carbon beams I use the Ampreg21 epoxy system from SP-Systems

All parts including the complete hulls will be post cured. Post curing is the process of exposing a part to elevated temperatures to maximize some of the material's physical properties. This can be done after the material has cured at room temperature for at least 12 hours. Although, there is no time slot.

An article very well worth reading about epoxy vs. polyester is on Kurt Hughes website, follow this link.

Laminating

Laminating is almost the same as wallpaper. At least, it is the same mess! All layers and extra reinforcements are laid in the same laminating process, wet in wet (wet-out and lay-up method). The resin is poured and spread over the glass fabric and excess resin as well as air bubbles are removed with a squeegee. When the laminate is getting clear the fabric is satisfied (not visible with carbon !). White spots are to dry and need to be wetted again.

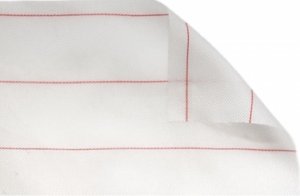

The last one layer is peelply, a nylon 80 g/m² release fabric, to which the epoxy resin will not adhere. The peelply absorbs excess resin and imparts a textured finished to the surface when removed, which minimises surface preparation before secondary bonding. It shows proper wet out and improves the surface finish by filling the weave and holding the glass flatter and it reduces the need for sanding.

Once the resin has cured, the peel ply can be pulled off to remove amine blush and expose fresh, uncontaminated resin surface that will require little if any sanding. Sanding the bare epoxy is a tricky business. It is very hard and unfriendly for yourself and for the sanding paper. But worse is the fact that sanding can damage the glass fabric. The peelply can remain on the part, protecting it against further contamination, until bonding or painting. Because the peel ply of itself is transparent in the laminate, at regular intervals a red line is woven in the fabric to recognize that it has been added to the laminate. Don't forget to remove!

I use peelply allover, hulls, panels, fillets, everywhere. I leave no uncovered fresh laminate, well, with a few minor exceptions on some barely accessible places that are ready without further secondary adhesion problems.

This hand-lay-up method is in principle sufficient when done right. However, layers are very thin and so there is little margin. Hand laid glass/foam boats often have bonding problems between the core and skin, as air is trapped in the open cells on the face of the core. That is not what I want and discovered that a vacuum treatment can improve the quality of the laminate by avoiding excessive resin and trapped air bubbles!

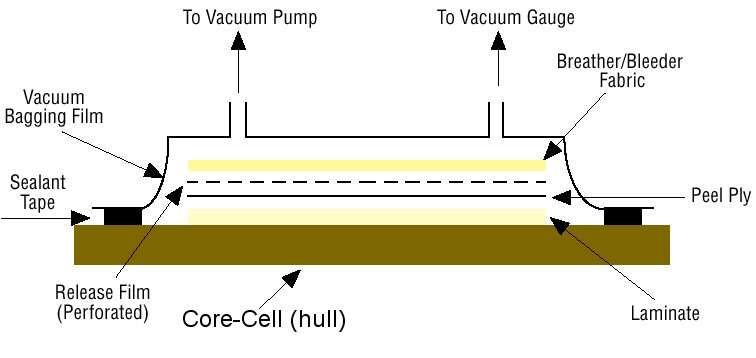

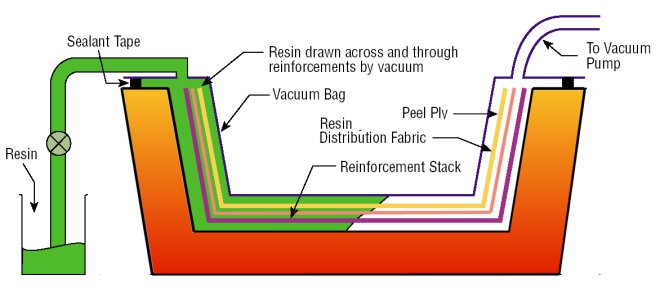

Vacuum bagging

Well let's face it, building this trimaran is a lot closer to building an aircraft than it is to traditional boatbuilding. So, one step further in achieving an absolute premium quality regarding to lightness, durability and strength is ″vacuum bagging″. The still uncured laminate is wrapped in a plastic bag while a vacuum pump creates a vacuum in the bag.

In this way all trapped air bubbles are soaked up and the whole laminate is under pressure for an better bonding with the foam surface without trapped air in the bonding area. A breather fabric allows the air to escape from all over the completed part and absorbs excess resin. The difficult part here is to airtight the bag without (too much) leakage. This vacuum bagging is an aerospace technique from origin, but is relatively simple to do once the principles are understood. At least for the small parts.

In this way all trapped air bubbles are soaked up and the whole laminate is under pressure for an better bonding with the foam surface without trapped air in the bonding area. A breather fabric allows the air to escape from all over the completed part and absorbs excess resin. The difficult part here is to airtight the bag without (too much) leakage. This vacuum bagging is an aerospace technique from origin, but is relatively simple to do once the principles are understood. At least for the small parts.

So, while in the process of preparing my skills, I realized that a vacuum densified laminate is getting high priority on my to-do-list. I also realized that the implementation of this technique is feasible for smaller components, but it still seems a challenge to do this on large hulls. The problem is that I am working on my own in a rather small workshop. The fact that this technique should start with old-fashioned hand lay-up and then to be completed within the time constraints of the resin clock currently looks very discouraging to me. For laminating and subsequent vacuum bagging the hulls are many helpers needed, for which I do not have enough space in my humble workshop. It also requires preparation in cutting the fabrics, mark and store them in a way they are immediately usable for the job.

An article in our local ″Zeilen″ magazine put me on the trail of the vacuum infusion technique. This has given me a whole new perspective on the matter. Although, at this time of preparations there was almost no information available, except that it was some kind of black magic, operated behind closed doors by some very professional boat building plants.

Vacuum infusing

The above schedule is almost the same, except that the bleeder fabric is replaced by a distribution fabric. The vacuum pressure is now used to drive the resin into the dry laminate instead. With this technique there is no messy hand-lay-up anymore. All fabrics are dry placed and after sealing the bag injected with epoxy, with the vacuum as the driving force. The progress of the resin through the layup can be monitored visually, and when complete, the inlets are clamped-off.

With this technique I can proceed piecemal with the layup, working alone in a spare hour here or there, putting the vacuum assembly together at a leisurely rate, and only when ready pulling a vacuum on the hull (or part), mixing the resin, and infusing.

Because the laminate is compressed prior to introducing epoxy, a more optimal ratio of resin to fabrics is obtained. And, not the least advantage, human exposure to potentially harmful epoxy vapors is minimized by reducing the time one actually works with the epoxy and the difficulty of what one has to do with it. It is merely mixing the epoxy and pour it into a bucket, from whence it is sucked in fully automated fashion into the laminate.

So Vacuum Resin Infusing is the way to go, being a real big step forwards and the most ultimate laminating method in my view.

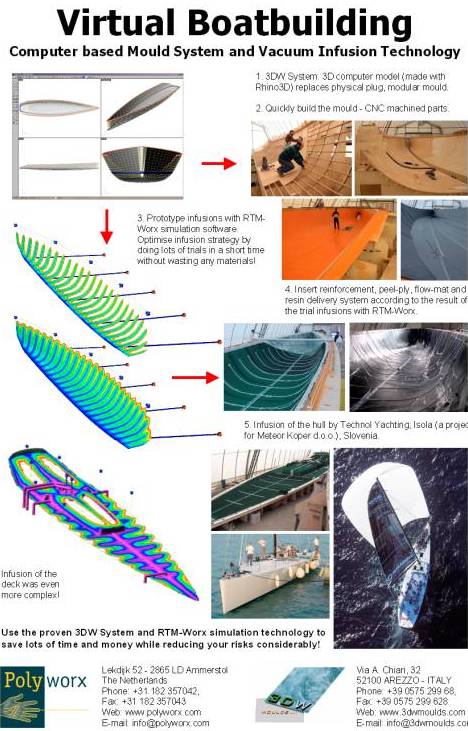

A breakthrough was made possible through the purchase of knowledge at Polyworx in the person of Mr. Arjen Korevaar. It turns out he is the developer of the very specialized flow software program, RTM-Worx, with which simulations of the process can be made in the computer prior to the actual infusion. Arjen familiarized me with the infusion technique, equipment and supplies and has given me the confidence that I can apply the infusion technique to my boat.

Most important for me is a reassurance that this technique provides a very high quality, both structurally and cosmetically, and that this is not dependent anymore on the human variable (my skill). Once the process has been designed, quality will be consistent.

The vacuum infusion technique is not only reserved for the construction of the hulls. Interior panels and bulkheads are also made with vacuum infusing. Here I use the double layer infusing system, where both laminates on each side of the foam core are infused simultaneously. For this purpose I made a flat table, covered with Formica to be perfectly flat. To realize a connection between both layers and to allow air and resin to escape from the bottom layer, the foam core needs perforations on a regular interval of about 25-50mm.

If you want to know more about vacuum, air pressure, units, pressure gauge, vacuum pumps and more please read my article called ″understanding vacuum″ in the ″About″ section of this site.

In the next chapter I explain more about the controlled vacuum infusion technique and its application in my building project. From my own experience I added an extensive listing of pros and cons of vacuum infusion versus vacuum bagging and hand-lay-up.

| « Previous Next » |