Construction of the floats ¹

The preparations for this boatbuilding adventure were fun and inspiring. Designer Ian Farrier gave me the address of fellow boat builder Gary Mulder, who is building an F-36 trimaran just an hour's drive from my home town. Gary gave me the opportunity to gain some practical knowledge by helping him and his wife laminate the layers of fiberglass on the outside of the F-36 main hull.

Laminating such a large hull was indeed a very instructive experience. Something that would be quite a challenge to carry out in my own small workshop / converted garage. It confirmed my intention that I should tackle it differently, apart from my lack of experience to carry out so much hand-lay-up laminating work. That is where the controlled vacuum infusion comes into play. See my considerations in the CVI chapter

Enjoy my first cautious steps in realizing Fram, so exciting!

Setup strong back and port float frames

At an earlier stage I got the used float form frames from Gary's F-36 to play with. Although the differences between the F-39 and F-36 frames-frames are considerable, I got a good idea of what to expect. The F-39 floats are 40 mm. wider and have a asymmetrical shape, giving them 15% more buoyancy. The outer half of the float looks to be slightly easier to make than the inside. That's why I started setting up these frames in the hope of learning the first tricks

Thermoforming the vertical foam strips

This is my first time building a boat with CoreCell foam and the answer to the question “How to bend the foam?”, has cost me a lot of sleep. However, this turned out to be pure and simple. But before that was recognized, I tried to make it much more complicated than necessary. So, the first attempt was with a “hot box”, main reason because other builders are doing this also (?!).

Fortunately too much of a pain for me and the hot box creation I made turned out to be unsuitable and disappeared in the garbage bin. But why always doing the things the hard way first? It was easy to bend the foam in place by just heating the foam with a heat gun while pushing it into the form.

For the vacuum infusion I need an airtight foam hull, so screwing down from inside through the foam is not possible. The 30 mm screws pass from the outside through the wooden slat in the back of the foam and remain 3 mm free from the inner foam surface. The strips are mounted “dry” and the joints between the strips are milled with a Dremel tool and filled with microballoons afterwards. This gives me the best assurance that the joints are sufficient impenetrable. The foam strips are 400 mm. wide in the middle of the hull to 300mm wide to both ends. With these economical sizes I can get 3 or 4 strips out of one plain sheet 4'x8' (1220x2440 mm.)

Controlled vacuum infusion

Flow simulation of the first float half. The RTM-Worx software makes it possible to eliminate the guesswork.

Now the biggest moment and the answer to the question “Will my approach to this boat building project be successful ??”

The answer is a heartily YES!

This is the best that happened to me lately. A building method with resin infusion with guaranteed results in the best quality one can think of and all that within my range of skills. The implementation in practice exactly meets the simulation model which is already very reassuring.

Amazing isn't it!

This first float half was a test but all lights are now green to continue the project and to order the other necessary building materials. This is no doubt a highlight and a good reason for a party.

(note: many years after writing the above, I learned that this one shot infusion of a hull together with elements such as stringers is called "3D infusion" (source European Boatbuilder Magazine no. 43 May 2010)

“Keel laying”

A good tradition when laying down the keel in a boat building project is the celebration of this milestone. Only problem with a trimaran is the absence of a keel (?!)

But this first infused hull half is a nice alternative to celebrate the successful start of Fram's life with a festively revelation of the hull by family and friends. (although I had to disappoint some friends who thought that this tradition would be repeated with each hull .......... )

Bulkheads

I made the first (and last) bulkheads with hand lay up and vacuum bagging before I discovered that vacuum infusion was a much easier method to do.

Among with other infusing details the infusion of the combined bulkheads (in one panel) for the next float is covered in a step-by-step video that's part of my resin infusion starters kit. (edit: not available anymore, only the CD content) In this album you can find also some photo's of the making of the foam stringers and cutting off the stern in the right shape.

Carbon fiber chainplate

Making of the carbon fiber chainplate. A stainless steel thimble on top of a foam strip, wrapped with UD carbon fiber. The chainplate is prepared for synthetic rigging with Precourt deadeyes. To maintain control over the straightness of the lay up of the carbon fibers, this part is not vacuum threatened.

With all these lessons learned it's becoming high time to start with the second hull half. Because of the limited room in my workshop, I have to make the second hull half of the same float now. This creates an extra setup of the form frames with the fore and aft battens. But I can do this quicker than moving the hull half for storing in another place. The new setup took less than 8 hours.

Unmolding and planking the second hull half

The hull halves are not symmetric, due to the raised deck area. The form of this half is not “self-releasing”, in other words, the raised deck area “hangs over”. This required an other setup of the battens in that area, which will allow to remove these battens while the hull is still in the form frames.

By the way, Ian Farrier recommends to leave this area unlaminated and to bent into shape after removing the hull from the form frames. This is probably easier with hand-lay-up lamination, but not suitable with my resin infusion technique.

Next resin infusion party

Most important thing I've learned is that any leakage is a no-go. Where I first thought an ultra sound leak detector is just a waste of money, I had to reconsider this opinion. So, I purchased one from Airtech to be able to find that very tiny bastard, virtually unnoticeable in this stage, but spoiling the fun during the infusion. On the other hand, some extra attention with the sealant tape will pay back. There is no rush to do this fast while there is no curing laminate as with the hand-lay-up vacuum bagging.

Pleats in the bag are unavoidable and even necessary to keep the bag from bridging. A spacious bag is no problem, but too tight is. So, these pleats are double sealed with the tacky tape. Making them is not difficult but requires some patient and handiness. Ones understood every sealed bridge will be tight, but if there are leaks in the bag this is the first place to start looking.

It is obvious that for a bag like this only dedicated vacuum materials are suitable, a strong vacuum film and a special sealant tape. Materials like the pvc or pe sheets one can buy at the local home-store and window seals or duck tape are a waste of money and energy. I tried the first bag with pvc, and it just did not work.

I made a video clip of the infusion of the second hull half. On special request from one of the e-group members on the Multihull Boatbuilders List I've added a John Williams sound track to catch the accompanying ambiance ;-) By the way, the video's in this page are the same as the one you can find in the Controlled Vacuum Infusion page.

Vacuum pump and resin trap setup

I use two small (but able to achieve a deep vacuum) oil filled rotation pumps, a fast running pump (in a former life used for maintenance purposes for medical MRI equipment) and a slow running (and almost antique) pump (after a long life in a scientific environment this pump is now used for his second multihull building) This one runs continues without any problem (the fast running pump is also able to run for a longer time, but is getting very hot, which I don't like while unattended) The only worry is to close the vacuum tube to the pump before switching of the power or to totally release the vacuum first. Otherwise the oil will flow in the resin trap, not really a problem, but a pity for the waste of oil.

Airtightness is crucial. I cannot afford any leakage, because this will ruin the laminate, making an air bubble track from leakage point to venting point. This is the advantage of a small pump. When there is some leakage the pump is not able to achieve a good vacuum. Here is a warning for big pumps justified, where a big pump is able to achieve a good vacuum while you don't know there is a leakage some where.

Making a tube

The wing nets are being attached to the hulls with a moulded lashing rail, made out of a tube. To get some experience with this system, I decided to make 3/4" tubes for attaching a net inside the float, as a floor to store sails and other stuff in a dry and ventilated matter, and not in the keel section of the float. Second advantage is that things are reachable from the deck hatch, without the need for going in. Although good enough for inside the float, I decided to buy ready made glassfibre tubes for the moulded lashing rail for the wing nets between main hull and floats.

Port float assembly

The float half still in the frames takes care for the correct shape, while the hull half on top is out of shape between the bulkheads. Once correctly aligned at both ends and bulkhead stations, this is not a real problem. With some temporally screws the shape of the hull half on top is easy corrected to the shape of the hull half below. With some bog between and taped bulkheads in the middle, the now joined hull is strong enough to release from the frames and, while turned in a convenient position, to go inside for taping the keel and deck join. I am happy with my four electrical winches in the ceiling, with which I can lift and turn the hull on my own.

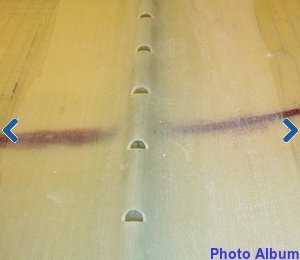

External laminate in one infusion shot

Now to the final climax for this hull, the vacuum infusion of the external laminate. The goal is to do the vacuum infusion in one single shot. To prevent the hull from being compressed, the air inside is connected to the outside world by means of a small hole. The calculated resin flow prediction looks like this:

|

I received a lot of questions about the area were the hull rest against the cradles. The thought is that the weight of the hull on the supports will disturb the epoxy flow by producing a compression force in the laminate. Well, this is only a (small) problem in the dry condition to keep the fabrics in their positions. During the infusion the vacuum pressure is about 1 kg/sqcm (this is 10 ton/sqm) and this force will overrule the weight completely. The epoxy flow is in not any way influenced by these supports.

Finishing the hull construction

Wingnet fastening is with an integrated molded lashing rail with a fiberglass tube. Another purpose of this rail is to create three strong deck eyes, as an alternative for bolted stainless steel pad eyes. The extra strength is created by carbon reinforced foam pads, which goes through the hull and are laminated to the inside, the middle one also in the shroud bulkhead.

Also the making of two deck hatches (with invisible hinges) and after all the glassing is done, the final post curing of the whole hull before the fairing is going on. The fairing and sanding turned out to be a real investment in learning time and finally succeeded by dogged perseverance. It's the last 300 gram of fairing compound that required the maximum effort.

The finishing of this first hull has been successful. Unfortunately, my euphoria needs to give way to a huge disappointment :(

Design change

After the summer holiday break I received an e-mail from Ian Farrier, announcing that the preliminarily drawings are now replaced by the final design plans, with some minor changes ......

One of them effected my job so far dramatic: the new designed beams are much wider and won't fit anymore between the raised deck area. So I had to take the saw for cutting some big holes, really not a nice job. The final fairing was just finished, but on the positive side, due to my sailing holiday I didn't cut in yet the lashing holes in the molded tube for the wing netting. So I can still distribute them evenly over the rail.

Of course I knew the design drawings were preliminarily but my motivation to start building was too intense to wait for the final drawings. My own fault.

Final paint work and storage

Finally the time is ready to move the hull to another storage. After the final paint job the hull is stored in another place, waiting for the assembly with her starboard twin sister.

Wow, first float is ready, check !

| « Previous Next » |