|

|

|

Note: This page is about controlled resin vacuum infusion. To get

a better understanding about "Vacuum" please have a look at this page called "Understanding

Vacuum". When I lose myself in the various laminating aspects, I find out that there are

some tricky and sticky moments in fabricating the composite parts, concerning:

1. Health.

I prefer to use

Epoxy instead of Polyester or Vinylester resins. Besides of the

smell (styrene), which will cause a nuisance to my family (our garage is the

workshop) and neighbors, epoxy resins

are far superior. I have been working with

epoxy for almost 25 years now and I am

still healthy yet. I want to keep it this way, as developing an epoxy allergy is still one of the

dangers.

Here are some quotes from other builders who

has been less lucky :-( So, a minimal exposure to epoxy is desirable.

2. Quality.

I can have sleepless nights about delaminating of the several layers and the

foam core (I myself having a wooden hart, a metal boat and a prejudgment against

"Tupperware" yachts). The bonding between the reinforcements (fabrics

saturated with epoxy) and the foam core is mechanical and not chemical. I want

to be my ship stiff, also after extensive use. I don't like a boat falling apart

after a heavy weather passage! As for this bonding as for the

reinforcement structure it's very important that there is no capture of air.

Voids in the laminate accelerate delamination and weaken the structure. That's why vacuum  bagging is a preferable technique, for a better laminate,

without voids, dry spots or resin rich spots, a good bonding between the glass layers and the foam core

and a better control of the glass to resin ratio. The process makes the

structure lighter, stiffer and stronger. I don't like secondary bonding

and want to make large and complicated structures in one shot. bagging is a preferable technique, for a better laminate,

without voids, dry spots or resin rich spots, a good bonding between the glass layers and the foam core

and a better control of the glass to resin ratio. The process makes the

structure lighter, stiffer and stronger. I don't like secondary bonding

and want to make large and complicated structures in one shot.

3. Weight.

I aim for an optimum quality, but also an optimum lightweight. I'm not that kind

of racer, well, maybe sometimes, but the lighter the boat the more cruising

stuff you can carry with you (still learning to get out of this bad habit). The

designer has reckoned a safety margin for structural integrity and the builder

have to have confidence in this. But in practice we boat builders tend to built much stronger as needed and it is

often quite

difficult to keep in check with this tendency. Instead of building heavier, I

want to find an extra margin in a save and accurate building method and in the

same time obey to my uncertainty and the (probably unnecessary) need for extra strength

without making concessions to the desired lightweight construction.

The

Solution: Controlled Vacuum Infusion. The

Solution: Controlled Vacuum Infusion.

VIP = Vacuum Infusion Process, VARTM = Vacuum Assisted Resin Transfer Molding,

RI = Resin Infusion, SCRIMP = Seeman Composites Resin Infusion Molding

Process, CVI - Controlled Vacuum Infusion, all these terms are covering

basically the same technique. The basic idea is simple: lay the

reinforcements materials up dry, compact them under vacuum, and then use the

vacuum to pull the resin in from outside the bag (or mold) which subsequently

progresses through the dry layup.

In the professional building environment this is a promising

technology for the production of large, high-quality, composite parts. This

technique uses one atmosphere of vacuum pressure to drive resin into a laminate. The reinforcement

materials are laid dry and the vacuum is applied before resin is introduced.

Once a complete vacuum is achieved, resin is literally sucked into the laminate

via carefully placed tubing. This

process adds improved worker conditions, emissions reduced to almost nothing and

considerable savings on labor costs. Another big advantage is that you can take

your time for laying out all of the laminations of glass and foam in a dry

environment and not under the pressure of a curing resin. When it is all ready

you can take the time to bag it and check it for leakage. After everything is

fine and checked, infuse it at your leisure, the same day, next week or at any

other moment. The only time you will even need to wear gloves is while mixing

the resin. No rollers, brushes or mess to clean up afterwards. No epoxy

fumes from a large wet area.

The vacuum infusion process

eliminates the inconsistencies of hand lay-up that's heavily dependent on laminator's

skill and it completely does away with air entrapment and void problems that can

compromise durability. There are no voids that can fill with water or paths for

potential water migration through the core. The process creates the highest

resin-to-glass ratio in yacht construction. This is the result of a 1/3 resin to

2/3 glass fiber ratio rather than the 2/3 resin to 1/3 glass fiber used in other

builder's processes. Higher glass fiber content results in greater strength to

weight ratio and a lighter, yet stronger composite laminate. The vacuum infusion process

eliminates the inconsistencies of hand lay-up that's heavily dependent on laminator's

skill and it completely does away with air entrapment and void problems that can

compromise durability. There are no voids that can fill with water or paths for

potential water migration through the core. The process creates the highest

resin-to-glass ratio in yacht construction. This is the result of a 1/3 resin to

2/3 glass fiber ratio rather than the 2/3 resin to 1/3 glass fiber used in other

builder's processes. Higher glass fiber content results in greater strength to

weight ratio and a lighter, yet stronger composite laminate.

However, in spite of all these advantages,

general acceptance has been slow, mainly due to the high risks involved with

trial-and-error methods due to just guesswork. Without a control method, all

materials and labor are wasted if the chosen injection strategy does not work.

Once infusion begins, there is little that can be done to correct any errors. It

is very easy to destroy a part and the best protection from disaster must be

careful planning. That's why most builders still stick to vacuum bagging,

producing high quality panels, where the excess resin content from the wet

hand-lay-up laminate is sucked by a bleeder under vacuum pressure (up to the breather/bleeder capacity). However, when

larger parts are made, vacuum bagging can become quite elaborate, or even

impossible.

As I've already explained in the FAQ section of this site, I prefer a vacuum

treatment of the laminate. So, how is Resin Infusion comparable to Vacuum

Bagging and hand-lay-up. From my own experience I will try to compare the pro's and

con's:

| |

Quality |

|

Hand lay-up |

|

Vacuum bagging |

|

Resin infusion |

|

| |

|

|

is the traditional wet laminate |

|

uses a sealed

plastic film to apply atmospheric pressure to the traditional wet laminate

in order to

remove some excess resin |

|

uses a sealed

plastic film to achieve a net vacuum on dry fabric in order to draw resin

through that fabric |

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

| |

Fiber to resin ratio |

|

-- |

|

+ |

|

++ |

|

| |

|

|

|

|

Instead of a dry laminate, vacuum bagging starts in an oversaturated state

of the laminate. A typical hand lay-up usually results in excess of 100%

fabric weight by resin. Vacuum pressure will remove much of the excess

resin, but the amount removed still depends on a variety of variables. |

|

Better fiber-to-resin ratio. Resin alone is very

brittle, so any excess will actually weaken the part. The reinforcement

materials are still dry, but compressed, when the resin is introduced. Any

excess resin will eventually be sucked out into the vacuum line. As a

result, only the minimum amount of resin is introduced. This lowers

weight, increases strength and maximizes the properties of fiber and

resin. |

|

| |

Heat build up |

|

+ |

|

+ |

|

-/+ |

|

| |

|

|

|

|

No heat build up. Most excess resin is collected in

the bleeder fabric, without an extreme heat build up. |

|

Excess resin is collected in the resin trap. With larger projects one have

to change resin traps to prevent accidents due to

extreme heat build up. |

|

| |

Amount of resin |

|

- |

|

- |

|

++ |

|

| |

|

|

|

|

The human variable is of great influence on resin usage. |

|

Less wasted resin. Due to the nature of vacuum

infusion, resin usage is very consistent and thus very predictable. Waste

can even be zero after some practice.

|

|

| |

Vacuum bag |

|

0 |

|

+ |

|

- |

|

| |

|

|

|

|

Less critical leaks. A leak in the bag will provide a

lower vacuum, but often will not really be fatal to the part. |

|

A leak in the bag can be fatal for the part. |

|

| |

Resin pot-life |

|

- |

|

- |

|

++ |

|

| |

|

|

|

|

The resin pot-life is extremely critical. Depending on when the vacuum

pressure is applied, the amount of resin removed can vary from part to

part. Bagging can quickly turn frantic when a pesky leak in the vacuum

seal cannot be found. |

|

The set up time is unlimited. Because the vacuum is

applied while reinforcements are still dry, there is no resin clock to

work against. After the bag is applied, leaks can be patiently sought out.

If something is not sitting properly, simply release vacuum and readjust.

No time constraints are introduced until it is decided that it is time to

infuse the resin. Until that moment, changes can be made again and again. |

|

| |

Tubing |

|

0 |

|

++ |

|

-- |

|

| |

|

|

|

|

Easy tubing. Vacuum bagging requires the placement of

only the vacuum tubing. |

|

Vacuum infusing requires the placements of vacuum tubing, resin inlets and

in-bag extensions of these tubes. The placements of these tubes are

critical and varies from part to part, depending on size and shape, and

there is no one way to set them up. These considerations must be evaluated

prior to lay-up. |

|

| |

Health |

|

-- |

|

-- |

|

++ |

|

| |

|

|

|

|

Vacuum bagging begins with a hand-lay-up laminate, with all the necessary

equipment and health precautions. The vacuum bag is applied to a wet

surface, with all the accompanying troubles to maintain a clean

environment and to prevent foul vacuum seals. |

|

Cleaner process. Vacuum infusion provides a cleaner,

safer and friendlier work environment. There are no brushes or rollers,

and therefore no splashing, spattering or dripping on yourself. There are

almost none resin fumes to contend with. It is merely mixing the resin and

pour it into a bucket, from whence it is sucked in fully automated fashion

into the laminate. |

|

| |

Quality risks |

|

-/+ |

|

+ |

|

- |

|

| |

|

|

|

|

Straightforward. Vacuum bagging begins with a

hand-lay-up laminate. When something goes wrong, one still can end with

this part, still suitable, however not as good as being vacuum bagged. |

|

Due to the complexity and ease of error in the infusion strategy, it is

very easy to destroy a part Once infusion begins, there is little that can be done to correct

a strategy error. |

|

| |

Quality |

|

- |

|

-/+ |

|

++ |

|

| |

|

|

|

|

The human variable is of great influence. |

|

Constant high quality. However, a correct infusion strategy is

necessary. |

|

| |

Overbleeding |

|

0 |

|

-- |

|

++ |

|

| |

|

|

|

|

Vacuum bagging can lead to overbleeding with a dry laminate as result. |

|

Constant high quality. However, a correct infusion strategy

and the right choice of materialsis

necessary. |

|

| |

Costs |

|

++ |

|

-/+ |

|

- |

|

| |

|

|

|

|

Extra costs for vacuum pump, vacuum bag, sealant tape, tubing, connectors,

release film and bleeder material. |

|

Extra costs for vacuum pump, vacuum bag, sealant tape, tubing,

connectors, release film and resin distribution material. Vacuum pump

must be able to achieve a high vacuum.

|

|

| |

Handling materials |

|

- |

|

-- |

|

++ |

|

| |

|

|

|

|

Not easy. |

|

Easy. All materials are used in a dry and clean

condition.

|

|

| |

Size of job |

|

+ |

|

-- |

|

++ |

|

| |

|

|

|

|

Larger lay-ups are only possible with the help of a lot of extra hands. |

|

Unlimited. Even large lay-ups are possible for a

single-handed builder.

|

|

| |

Mix quality |

|

-- |

|

-- |

|

++ |

|

| |

|

|

|

|

Risk of inaccuracy.

Larger lay-ups requires a lot of small mixing batches. |

|

Accurate. One or more big batches for a

large lay-up improves the quality of the mix and reduces the chance of

mixing errors.

|

|

| |

Multiple layers |

|

- |

|

-/+ |

|

++ |

|

| |

|

|

|

|

The more layers the more awkward |

|

Excellent wetting out, even the exotic

fibers and sometimes the only way to be sure.

|

|

| |

Time |

|

++ |

|

-/+ |

|

+ |

|

| |

|

|

|

|

Extra time is needed for applying vacuum materials and vacuum bag. Once

the hand-lay-up has started, there is no way back and one has to finish

the job.

Wetting-out and squeegee work is time consuming

and not very forgiving and there is additional time involved with

getting the bag and other stuff on while the resin is kicking off,

adding time to an already long and potentially hectic process. |

|

At your leisure. Approximately the same as with vacuum bagging but

because of the absence of the "resin clock" one can divide the job in more

smaller jobs and at a moment that suits best.

A

single person can take as long as they like to drape the fibers, apply

release cloth and flow media, seal the bag, and check for leaks. Having

a much more forgiving timeline one can spread this out over many

evenings after work, and could walk away or be interrupted at any time

without consequence.

|

|

| |

Simultaneous sandwich laminating |

|

-- |

|

-/+ |

|

++ |

|

| |

|

|

|

|

A pity it has to start with hand-lay-up |

|

Try it yourself. Buy

the RI Kit. |

|

I never thought of the possibilities to use this Vacuum Infusion technology by me as a

part time boat builder. But, technologies are developing fast and why should I not

benefit from these advantages. I became

enthusiast when I discovered this

technique while successful used by the building of a one-off 44 ft. leaner.

The key factor in this success, and the reason why I am able to use resin

infusion for building my boat, is the use of a very specialized software

program, RTM-Worx, and the accompanying advice by the developer of this software

Mr. Arjen Korevaar from Polyworx.

The flow simulation software makes it possible to eliminate the guesswork.

Injection strategies that do not work are quickly eliminated and new ways to

infuse parts can be tried out without any risks. It is not necessary to do

costly trials and no labor or materials are wasted with the capability to test

it on the PC first. The simulation code is based on the Finite Element and

Control Volume methods to solve the physical equations that govern flow of a

resin through a porous medium.

When CAD-files are available it is possible to import 3D models from STL, DXF

and PATRAN files. However, the availability can be a problem due to copyright,

license and or confidential aspects. Most designers are uncomfortable supplying

these CAD files - the America's cup guys even get upset if someone looks at

their hull through binoculars. As Mr. Ian Farrier explained to me, it is like

Microsoft gives away the full source code of windows.

The RTM-Worx software however is also equipped with an integrated geometry

editor. With this function you can enter your own 3D model.

|

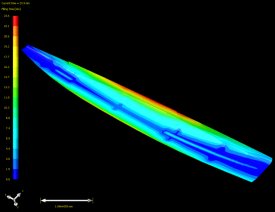

It took me four days to

digitalize the Full Size Patterns of the F-39 to an enough accurate 3D model. So

I provide the station lines in the Full Size Patterns with diagonal

lines and thus created a three-dimensional grid. I entered the

corresponding digits in RTM-Worx and joined this key points with curves,

et voila.... |

|

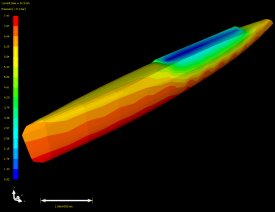

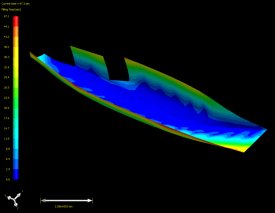

Click one of these 3D models for more views.

Next step with these models is to add runners, injection and venting ports,

direction of gravity, resin and fabric properties. In the next pictures you can

find the calculated moving animations of the infusion process for the various

hulls and some video's showing the real live infusion of these parts.

Enjoy.

The first infusion experience is with the first float half.

Above image is the

calculated animation, Click on the float image for the moving animation.

I made a video clip of the infusion of the second hull half. On special request

from one of the e-group members on the Multihull Boatbuilders List I've added a

John Williams sound track to catch the accompanying ambiance ;-) |

|

Now the infusion of the outer side of the joined

float is an other story. My goal was to do this in one shot ... and it

happened, a real party, I can assure you. Click on the float to see the computer

simulation. |

|

| The infusion video of the last float half. |

|

| The video of the infusion of the second float, also in one injection shot. |

|

In the above image the animated simulation of the first main hull half.

Video is at the right. |

|

| The video of the infusion of the second mainhull half. |

|

| The video of the infusion of the mainhull bottom |

|

| The video of the infusion of the mainhull deck |

|

| The video of the infusion of the escape hatch |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

|

| |

|

| |

|

| |

|

|

|

|

| |

|

Do-it-yourself

Vacuum Resin Infusion Starter Kit

The art of infusing various components can seem

daunting at first. It all seems a bit complicated. However, its

difficultly depends solely on the complexity of the part. For

example infusing a flat sheet is simple and relatively straight forward.

I receive a lot of questions about this Resin

Infusion technique, which made me thinking of a way to make this easier

understandable and within practical reach for other builders. When

knowing the principles and understanding of why the resin flows as it flows, it

all will become much easier.

For

infusing simple shapes as panels and bulkheads, you really don't need any

software to do so, just some common sense and a way to overcome all

beginners failures while doing it the right way from the beginning,

without wasting expensive composite materials.

So, here is

the solution to enter the world of Resin Infusion.

Talking about bulkheads and panels several sources are

trying you to believe that vacuum infusion is more work or much slower

than vacuum bagging.

I can assure you it is not!

They also discourage the double layer infusing system, where

both laminates on each side of the foam core are infused simultaneous.

Ridiculous really!

I will learn you how to do this without any risk and with

guaranteed success.

Please try!

Good luck !!

|

|

|

| |

|

|

|

|

|